Join Our Team - Pacific Northwest Region We are looking to add another experienced sales professional to our ever-growing team. Are you or someone you know a fit? Send your resume to sales@nwinstruments.com.

Systems Conference and Exhibit show in Billings MT June 26th-27th 2018

NIC will be attending this year’s Control Systems Conference and Exhibit show in Billings MT June 26th-27th 2018 Location: Red Lion Hotel 1223 Mullowney Ln, Billings, MT 59101 (406) 248-7151 Northwest Instrument & Controls Linecard [siteorigin_widget class="WP_Widget_Custom_HTML"][/siteorigin_widget]NIC Sponsored training courses: EPA Refinery Sector Rule Complieance and Real-Time...

Drexelbrook Universal IV CM water cut monitor

The Drexelbrook Universal IV CM water cut monitor is a state-of-the-art water measurement instrument used to accurately determine the amount of water and oil.

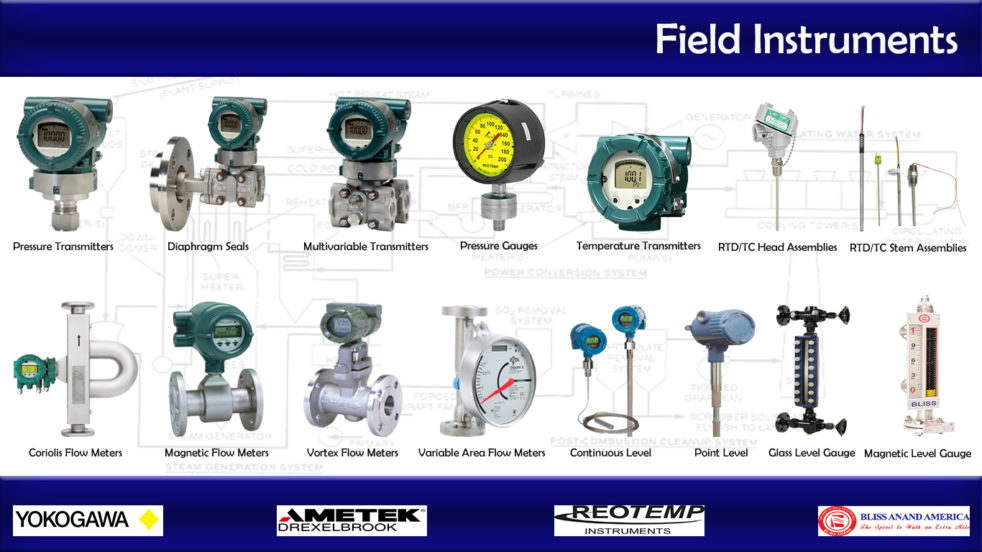

Field Instrumentation

Yokogawa AMETEK DREXELBROOK Reotemp instruments Bliss Anand America Pressure Transmitters Temperature Transmitters Multivariable Transmitters RTD/TC Head Assemblies RTD/TC Stem Assemblies Pressure Gauges Diaphram Seals Coriolis Flow Meters Magnetic Flow Meters Vortex Flow Meters Variable Area Flow Meters Continuous Level Point Level Glass Level Gauge Magnetic Level Gauge